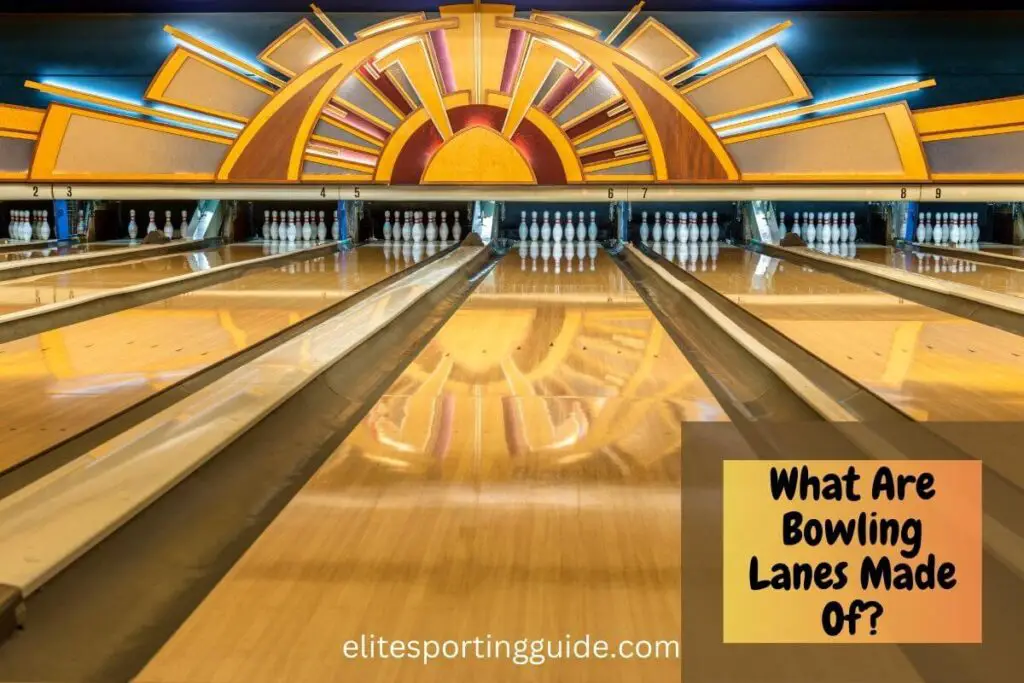

“What Are Bowling Lanes Made Of?” Curious minds often wonder about the materials that comprise the foundation of these bowling spaces

In this article, we zoom in on the construction of bowling lanes, examining the various components such as the approach, lane bed, pin deck, and lane finish.

By uncovering the materials used and their significance, we aim to provide a comprehensive understanding of the composition and engineering behind these integral elements of the game of bowling.

So, let’s embark on this journey to discover what lies beneath the polished surfaces of bowling lanes.

What Are Bowling Lanes Made Of?

Bowling lanes are typically made of a combination of materials including hardwood, such as maple or pine, for the approach area, and either solid laminated maple wood or synthetic materials like synthetic laminates and polymers for the lane bed. The lane finish can vary, but it may consist of a textured surface or a thin layer of oil to affect ball movement.

The Approach: Sturdy Hardwood for the Bowler’s Stance

The approach is a fundamental component of a bowling lane, serving as the area where bowlers stand and prepare to release the ball.

It is essential for the approach to provide a sturdy foundation and reliable grip to ensure consistent and confident footwork. This is why sturdy hardwood, such as maple or pine, is commonly used in constructing the approach.

Hardwood materials offer several advantages for the approach. Maple, known for its durability and resilience, is a popular choice due to its ability to withstand constant foot traffic and maintain its structural integrity over time.

Its natural grain pattern provides a textured surface that enhances traction, allowing bowlers to maintain stability and control during their approach.

Pine is another hardwood often used for the approach, prized for its lighter weight and softer feel underfoot. It can offer a different level of grip and is preferred by some bowlers who appreciate its unique characteristics.

To maintain the quality and performance of the approach, regular maintenance and refinishing may be necessary. This ensures that the hardwood remains smooth, level, and free from imperfections that could affect a bowler’s stance and release.

The choice of sturdy hardwood materials, such as maple or pine, for the approach of a bowling lane is decisive for providing bowlers with a solid foundation and reliable grip.

The texture and durability of these materials contribute to a consistent and confident approach, allowing bowlers to focus on their technique and achieve optimal performance on the lanes.

Lane Bed: From Solid Maple to Synthetic Surfaces

The lane bed is a central component of a bowling lane, serving as the main playing surface where the bowling ball rolls towards the pins.

Traditionally, solid maple wood has been the material of choice for constructing the lane bed. Solid maple offers exceptional durability, strength, and a smooth surface that allows for consistent ball movement.

The density of maple wood helps absorb the impact of the bowling ball, minimizing excessive rebound and providing a more controlled roll.

In recent years, synthetic surfaces have emerged as a popular alternative to traditional solid maple lane beds. Synthetic materials, such as synthetic laminates, resins, and polymers, offer several advantages.

They provide a more consistent playing experience as they are manufactured to precise specifications, ensuring uniformity across all lanes in a bowling center.

Synthetic surfaces also require less maintenance compared to solid wood. They are less susceptible to warping or changing due to temperature and humidity variations, resulting in a more stable playing surface over time.

Moreover, synthetic lane beds offer increased versatility in lane customization. Various patterns, textures, and colors can be applied to the synthetic surface to enhance ball reaction and aesthetics.

These customizable options allow bowling centers to create unique lane conditions and cater to different skill levels and playing preferences.

Whether it’s the traditional solid maple or the modern synthetic surfaces, the construction of the lane bed plays a vital role in determining the overall performance and consistency of the bowling experience.

The choice between these materials often depends on factors such as maintenance requirements, desired playing conditions, and the specific needs and goals of the bowling center.

Pin Deck: Durability and Precision for Pin Placement

The pin deck is a key element of a bowling lane that serves as the area where the pins are set up for each frame. It plays a significant role in ensuring the durability and precision of pin placement during gameplay.

To withstand the repeated impacts of bowling balls and maintain accuracy, the pin deck is constructed using materials that offer both resilience and reliability.

One commonly used material for the pin deck is hard maple.

Hard maple wood provides the necessary toughness to withstand the constant force exerted by bowling balls as they collide with the pins.

Its dense composition helps absorb the impact and prevent excessive wear and tear, ensuring that the pin deck remains robust and functional over time.

In addition to hard maple, synthetic materials such as high-density plastic are also utilized for pin decks. These synthetic materials offer enhanced durability and resistance to damage caused by repeated impacts.

High-density plastic can withstand the force of bowling balls while providing a smooth surface for pins to stand on, allowing for accurate pin placement and minimizing pin deflection during gameplay.

The precision of pin placement is essential for maintaining the integrity of the game and ensuring a fair playing experience.

The durability of the pin deck materials, whether it’s hard maple or synthetic alternatives, ensures that the pins are consistently positioned in their designated spots after each ball roll, enabling accurate scoring and a satisfying gameplay environment.

In summary, the pin deck is constructed using materials such as hard maple or high-density plastic to ensure durability, precision, and accuracy in pin placement.

The choice of materials depends on factors such as desired longevity, maintenance requirements, and the specific needs of the bowling center.

By providing a reliable foundation for the pins, the pin deck contributes to the overall integrity and enjoyment of the game of bowling.

Lane Finish: Enhancing Performance with Texture and Oiling

The lane finish is a crucial aspect of a bowling lane that directly impacts the performance of the bowling ball. It involves applying specific treatments to the lane surface to enhance the ball’s motion and control.

The lane finish serves two primary purposes: providing the right amount of friction or slipperiness and protecting the lane surface from wear and tear.

Traditionally, oiling has been a common method used to modify the lane finish. A thin layer of oil is applied to the lane surface to create a controlled level of friction.

The oil pattern can be adjusted to influence ball movement, such as increasing or decreasing hook potential or altering ball skid.

The oil serves as a lubricant, allowing the ball to slide smoothly during its approach before encountering the friction on the lane, affecting its trajectory.

However, with the rise of synthetic lane surfaces, the need for frequent oiling has been significantly reduced.

Synthetic lanes often feature a textured surface that offers inherent friction, reducing the reliance on oil patterns.

The textured finish provides consistent grip and ball reaction, reducing the variation caused by changing oil patterns and offering a more predictable playing experience.

Regardless of the specific lane finish, regular maintenance is essential to ensure optimal performance.

Cleaning and resurfacing the lane periodically help remove debris, dirt, and excess oil build-up, allowing the lane to maintain its desired level of friction and slipperiness.

The lane finish plays a vital role in enhancing the performance of the bowling ball. Whether through the application of oil or the utilization of textured synthetic surfaces, the goal is to achieve the desired amount of friction or slipperiness for the ball’s movement.

The lane finish not only affects the ball’s trajectory but also helps protect the lane surface, ensuring a consistent and enjoyable bowling experience for players.

Traditional vs. Modern Bowling Lane Construction

Traditional and modern bowling lane construction methods have evolved over time, reflecting advancements in materials, technology, and player preferences.

Let’s compare the two approaches:

1. Traditional Construction: In traditional bowling lane construction, solid materials such as hardwood, particularly maple, were predominantly used. Hardwood provided durability, stability, and a reliable playing surface.

The approach, lane bed, and pin deck were all made of solid maple, meticulously crafted to create a consistent playing experience. The lane finish involved regular oiling to manipulate ball movement.

2. Modern Construction: Modern bowling lane construction has seen the introduction of synthetic materials, such as synthetic laminates, resins, and polymers, as alternatives to solid wood.

Synthetic lane beds offer consistent performance, reduced maintenance, and increased resistance to warping or changing due to environmental factors.

Synthetic surfaces often have a textured finish that provides inherent friction, reducing the need for frequent oiling the pin deck may also be constructed using high-density plastics for enhanced durability.

Advantages and Considerations

Traditional construction offers the familiarity of solid wood, providing a unique playing experience appreciated by many bowlers.

The natural characteristics of hardwood, such as its grain pattern, can influence ball movement in subtle ways.

However, traditional lanes require more maintenance, including regular sanding and oiling, to maintain their optimal condition.

Modern construction with synthetic materials offers advantages in terms of durability, consistency, and reduced maintenance. Synthetic lanes tend to be more resistant to wear and tear, require less oiling, and provide a predictable ball reaction.

They also offer customization options, such as color and surface textures, to create unique lane conditions. However, some bowlers may prefer the feel and nuances of traditional wood lanes.

Traditional bowling lane construction relies on solid hardwood materials and regular oiling for ball movement control.

Modern construction embraces synthetic materials for improved durability, consistency, and reduced maintenance.

Both approaches have their merits, and the choice between them often depends on factors such as player preferences, maintenance capabilities, and the desired bowling experience in a particular bowling center.

Maintenance and Considerations for Bowling Lane Materials

Maintenance plays an all-important role in preserving the performance and longevity of bowling lanes, regardless of the materials used in their construction. Here are some important considerations and maintenance practices for bowling lane materials:

1. Regular Cleaning: Regularly cleaning the bowling lanes is essential to remove dirt, dust, and oil build-up. Use approved lane cleaners and follow manufacturer recommendations to maintain the lane’s playing surface.

2. Resurfacing: Over time, bowling lanes may develop scratches, nicks, or wear patterns. Resurfacing the lanes periodically helps restore a smooth and even playing surface. This process involves sanding down the lane to remove imperfections and applying a fresh finish.

3. Oiling: If the lanes feature a traditional wood surface, regular oiling is necessary to maintain the desired friction and ball reaction.

Apply oil using approved lane oiling machines and follow oiling patterns recommended by bowling lane professionals or manufacturers.

4. Synthetic Lane Maintenance: Synthetic lanes require less frequent oiling but still require regular cleaning and maintenance.

Remove dirt and debris using approved cleaners and equipment suitable for synthetic surfaces. Follow manufacturer guidelines for specific care instructions.

5. Environmental Considerations: Temperature and humidity can affect the performance and condition of bowling lanes. Maintain a stable environment within the bowling center, as fluctuations in temperature and humidity can cause wood lanes to warp or synthetic surfaces to expand or contract.

6. Inspections: Regularly inspect the lanes for any signs of damage, such as cracks, loose boards, or pin deck wear. Address any issues promptly to prevent further damage and ensure a safe playing environment.

7. Professional Maintenance Services: Consider partnering with professional lane maintenance services or experts who specialize in bowling lane care. They can provide in-depth inspections, maintenance, and resurfacing services to keep the lanes in optimal condition.

Maintenance practices may vary depending on the specific materials and construction techniques used in the bowling lanes.

It’s essential to consult manufacturer guidelines, industry professionals, or lane maintenance experts for the most accurate and up-to-date recommendations regarding the care of your bowling lanes.

Related post: How Often Do Bowling Alleys Oil Their Lanes

Innovations and Future Trends in Bowling Lane Construction

Bowling lane construction has seen several innovations and advancements in recent years, driven by the pursuit of improved performance, enhanced player experiences, and technological advancements.

Here are some notable innovations and future trends in bowling lane construction:

1. Advanced Synthetic Surfaces: Synthetic lane materials continue to evolve, offering enhanced durability, improved consistency, and reduced maintenance requirements.

Manufacturers are developing advanced synthetic surfaces with proprietary blends of polymers and coatings, resulting in surfaces that closely mimic the characteristics of traditional wood lanes while providing increased durability and predictability.

2. Customizable Lane Conditions: Bowling centers are embracing the ability to create customizable lane conditions using innovative lane surfaces and oiling techniques.

Lane surfaces with interchangeable panels or inserts allow bowling centers to modify the lane’s characteristics, such as the level of friction or oil absorption, to cater to different playing styles or competition requirements.

This customization empowers bowlers to adapt their strategies and offers a more diverse and engaging bowling experience.

3. Integrated Technology: Technology is becoming increasingly integrated into bowling lane construction. From digital scoring systems to automated lane maintenance equipment, advancements in technology are revolutionizing the way lanes are managed and operated.

Real-time data collection and analysis tools provide valuable insights into lane conditions, ball performance, and player statistics, allowing for better lane maintenance and a more immersive experience for bowlers.

4. Environmentally Sustainable Materials: As environmental consciousness grows, there is a rising interest in using sustainable materials in bowling lane construction.

Manufacturers are exploring eco-friendly alternatives such as reclaimed wood, recycled synthetic materials, and bio-based polymers.

These materials not only reduce the environmental impact of bowling lane construction but also offer comparable performance and durability.

5. Augmented Reality and Virtual Reality: The integration of augmented reality (AR) and virtual reality (VR) technologies into bowling lane construction opens up new possibilities for immersive gameplay experiences.

AR overlays can provide real-time information, such as ball speed, trajectory, and pin placement, enhancing the visual feedback for bowlers.

VR simulations can transport bowlers to virtual bowling environments, offering unique challenges and entertainment options.

6. Hybrid Lane Surfaces: Hybrid lane surfaces combine the best characteristics of different materials, blending traditional wood with synthetic elements.

These hybrid surfaces aim to provide the desired aesthetics, performance, and longevity by combining the natural feel and ball reaction of wood with the durability and consistency of synthetic materials. Hybrid lanes offer a balance between tradition and innovation.

Bowling lane construction is undergoing a continuous evolution, driven by innovations and advancements in materials, technology, and player demands.

With improved synthetic surfaces, customizable lane conditions, integrated technology, sustainable materials, augmented reality, and hybrid surfaces, the future of bowling lane construction promises exciting possibilities that enhance the game’s performance, engagement, and sustainability.

The Science Behind a Perfect Bowling Lane: Factors Affecting Ball Movement

A perfect bowling lane is the result of careful engineering and consideration of various factors that influence the movement of the bowling ball.

Understanding the science behind these factors is essential for creating optimal lane conditions and enhancing the overall bowling experience. Here are some key factors that affect ball movement on a bowling lane:

1. Friction: Friction between the bowling ball and the lane surface plays a critical role in determining the ball’s speed, hook potential, and overall trajectory.

The frictional force generated between the ball and the lane is influenced by factors such as the lane material, surface texture, oil pattern, and ball composition. Balancing the right amount of friction is crucial to achieve the desired ball motion.

2. Lane Surface: The material used for the lane surface significantly impacts ball movement. Traditional wood lanes offer a unique feel and interaction due to the natural characteristics of the wood, such as grain patterns.

Synthetic lanes provide a consistent and predictable surface that requires less maintenance. The smoothness, hardness, and texture of the lane surface influence the level of friction and ball reaction.

3. Oil Pattern: The application of oil on the lane surface is a critical aspect of lane conditioning. The oil pattern determines the distribution of oil across the lane, affecting the ball’s skid, hook, and roll.

Different oil patterns, such as house shots or sport patterns, can create varying levels of friction and challenges for bowlers. The length, volume, and placement of the oil pattern influence ball motion and lane playability.

4. Ball Surface: The surface of the bowling ball itself influences its interaction with the lane. The ball’s coverstock, finish, and texture affect its ability to grip the lane and generate friction.

Bowlers can adjust the ball’s surface by using abrasives or cleaners to enhance or reduce friction based on lane conditions.

5. Lane Topography: The topography or contour of the lane surface can impact ball movement.

Even slight irregularities, such as flat spots or depressions, can cause the ball to deviate from its intended path. Maintaining a smooth and level playing surface is fundamental for consistent ball motion.

6. Lane Maintenance: Regular lane maintenance is necessary to ensure optimal ball movement. Cleaning the lanes, resurfacing, and re-oiling help maintain consistent lane conditions and minimize variations in ball reaction. Proper maintenance practices help preserve the integrity of the lane surface and enhance the overall bowling experience.

Understanding and controlling these factors allow bowling centers to create a variety of lane conditions to accommodate different skill levels, challenges, and preferences.

Through careful manipulation of friction, lane surface, oil patterns, ball surfaces, topography, and maintenance practices, the science behind a perfect bowling lane is harnessed to provide an engaging and enjoyable experience for bowlers of all levels.

Post you may be interested in: Are Bowling Balls Heavy?

Unraveling the Craftsmanship of Bowling Lanes

The craftsmanship behind bowling lanes is a testament to the dedication and precision required to create an optimal playing environment.

Whether it’s the selection of materials, the construction techniques, or the fine-tuning of lane conditions, every aspect is designed to ensure a consistent and enjoyable bowling experience.

The attention to detail and the mastery of the science behind ball movement contribute to the artistry of bowling lane construction, allowing bowlers to engage in the sport they love with precision and skill.